Technology

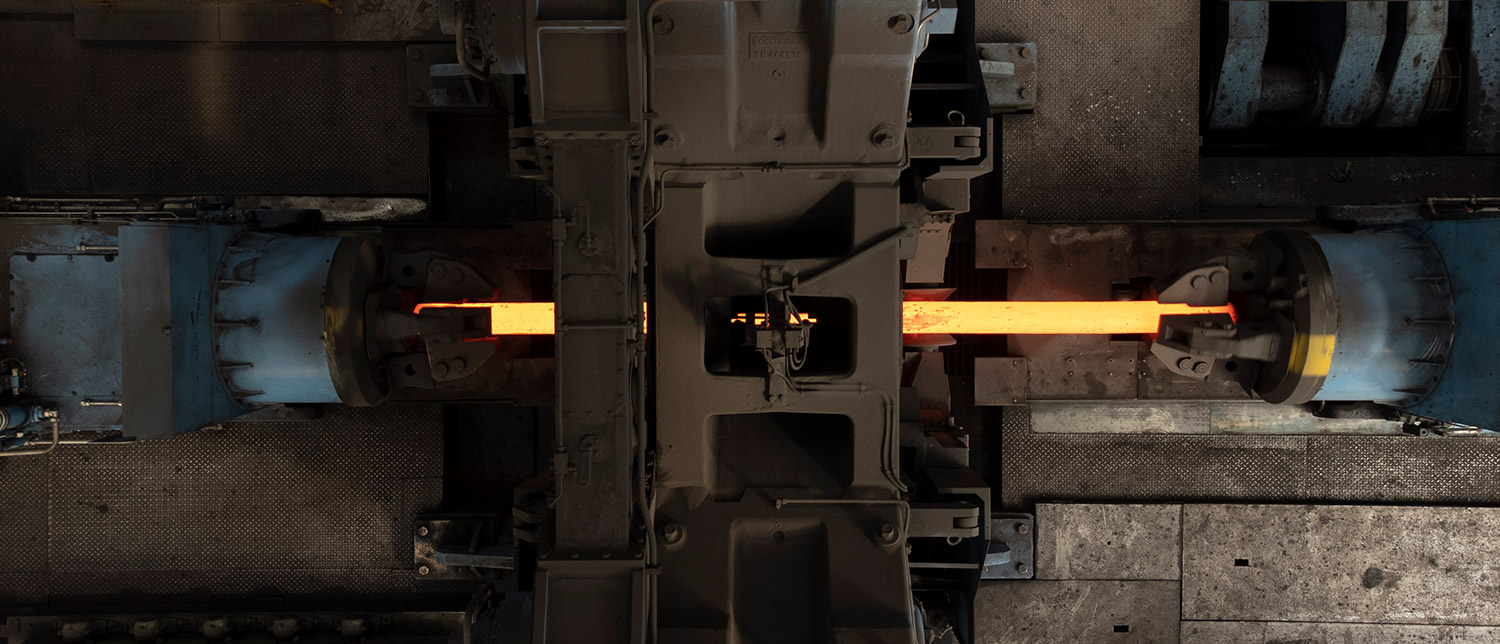

Our plants are the result of large investments in innovation and technology.

The key word is cutting edge: our commitment is to invest and train to ensure constant growth and technological innovation.

Our expertise and targeted technological investments allow us to accept and face with awareness and determination the challenges that the market offers us. Our technical production capacity and well-established know-how allow us to comprehensively incorporate the entire market niche across the board, while maintaining quality and production flexibility.

AUTHENTIC STEEL EXPERTISE

The investment in state-of-the-art technologies and plants testifies our commitment to ensuring:

STANDARD OF QUALITY

CHEMICAL AND PROCESS CUSTOMIZATION

HIGH PRODUCTION FLEXIBILITY

Plants with high technological value

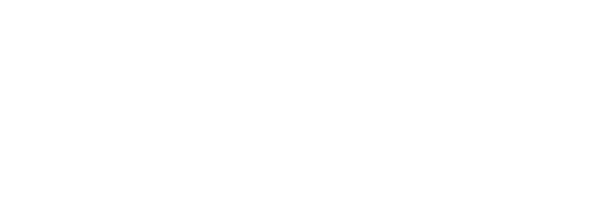

ESR

Closed ESR, cold start process

Ingot diameter up to 1350mm

Ingot length max 3560mm

Furnace Capacity 40ton

VAR

Ingot diameter up to 1230mm

Ingot length max 3500mm

Furnace Capacity 30ton

VIM – VIDP

Furnace capacity 30ton

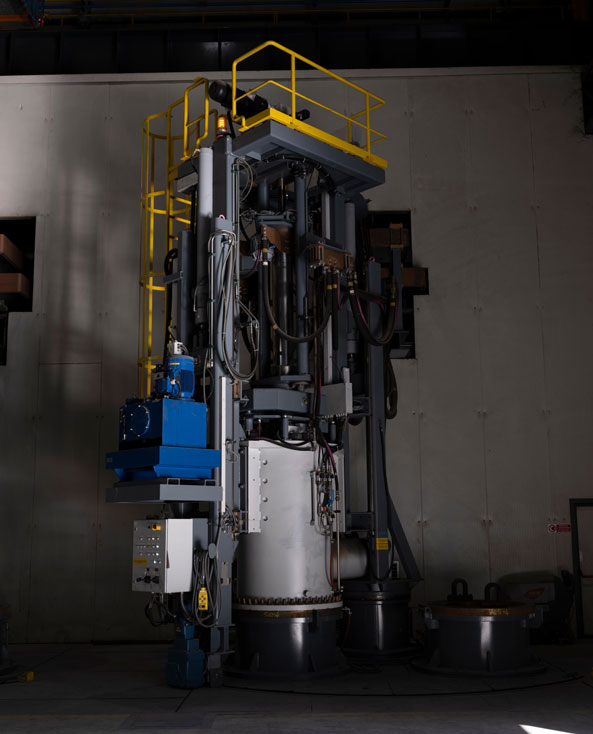

GFM

4 hammers

Max forging force 9500kN

Max forging power 1200kW

Max out dia 400mm

Min out dia 100mm

Max out length 9500mm

Heat treatment furnaces

Two solubilization treatment furnaces (one AMS 2750 compliant)

One ageing and tempering AMS 2750 compliant furnace

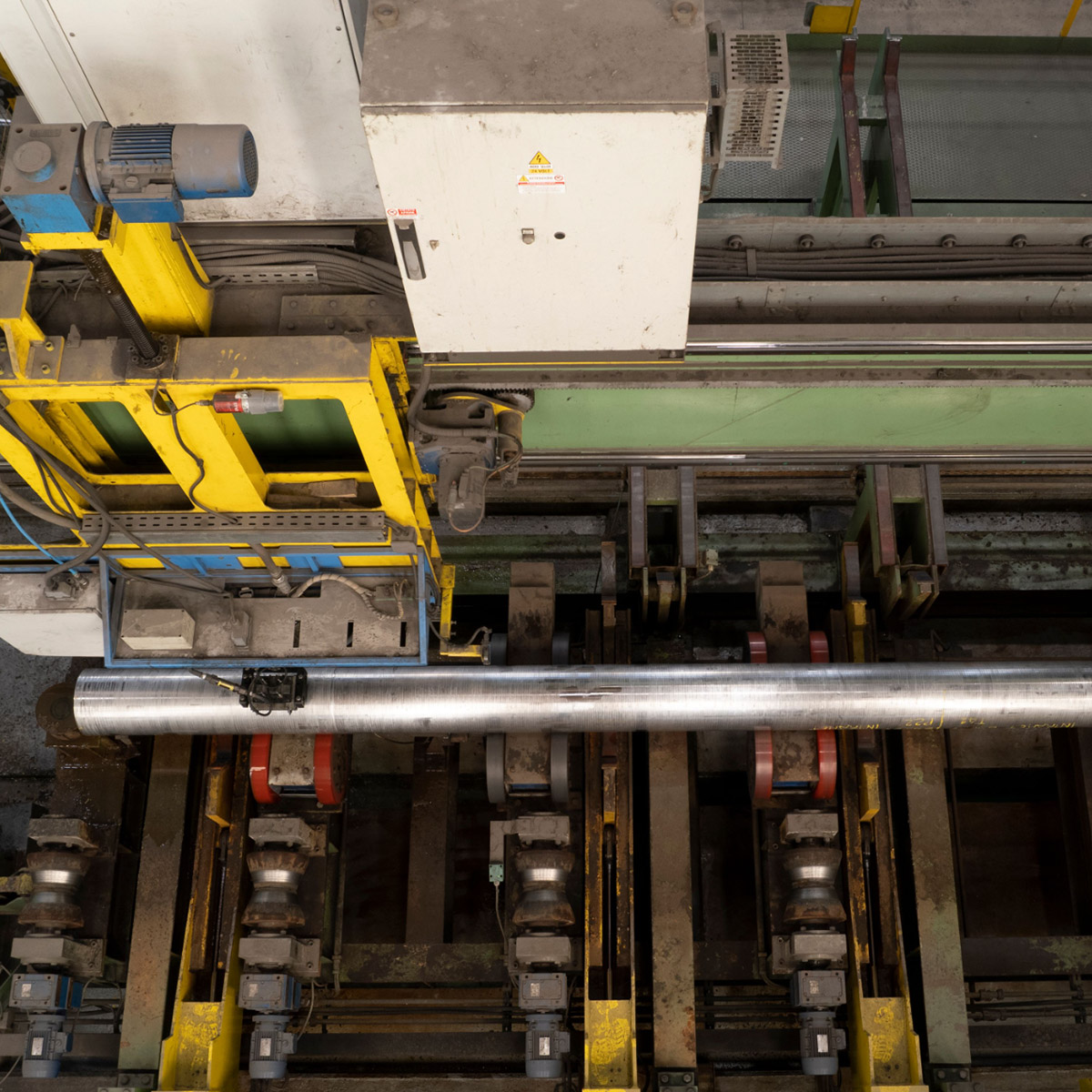

UT

Semiautomatic Ultrasonic Testing machine

Phased Array Module (64 elements)

Bar 115mm-400mm